The first excuse I can find, I'll be selling my printer and buying one of them fancy new Bambus. Those things are sexy.

Ontopic The 3D printing thread

- Thread starter gee

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jehannum

Puts the "pro" in procrastination

I'd Swayze the fuck out of that.Missus at the local makerspace had a broken pottery wheel. 3D printer to the rescue!

View attachment 17908View attachment 17909View attachment 17910View attachment 17911View attachment 17912

Jehannum

Puts the "pro" in procrastination

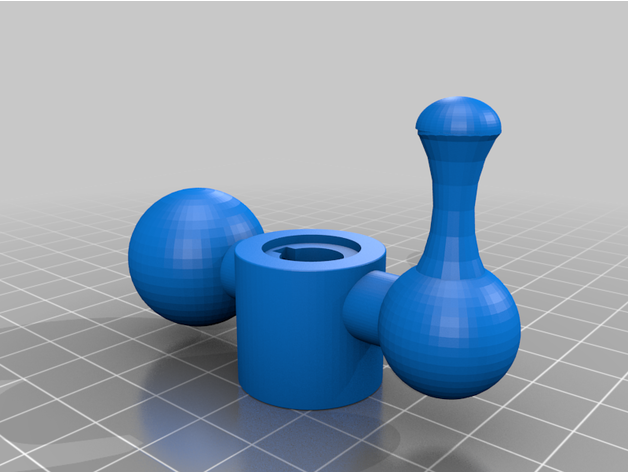

The boy knocked out replacement crossfeed and compound handles for my old Atlas lathe in tinkerCAD.

They'd been on my "to do" list for a while, but he wanted to have a go yesterday and I won't say no to that.

The old zamak ones were (common theme here) broken. He doesn't really know slicer settings for anything but PLA, so I'll print them up in ABS or Taulman 910 and replace the old ones. Probably also do Tubalcain's big dials too, as mine are pretty unreadable.

He put them up on thingiverse, as it might save someone else the $20 nearly the exact same thing sells for on eBay (who'd have thought selling 3D printed shit on ebay would be a thing?)

www.thingiverse.com

www.thingiverse.com

They'd been on my "to do" list for a while, but he wanted to have a go yesterday and I won't say no to that.

The old zamak ones were (common theme here) broken. He doesn't really know slicer settings for anything but PLA, so I'll print them up in ABS or Taulman 910 and replace the old ones. Probably also do Tubalcain's big dials too, as mine are pretty unreadable.

He put them up on thingiverse, as it might save someone else the $20 nearly the exact same thing sells for on eBay (who'd have thought selling 3D printed shit on ebay would be a thing?)

crossfeed knob for Craftsman Atlas 12 inch lathe by walker67079

the knob was measured in metric units not imperial units

Jehannum

Puts the "pro" in procrastination

Needed a 4.5° angle stop to set the fence on my Hobo Freight benchtop band saw in the "chop" setting, so I made a parametric angle stop (you can adjust the angle, the length, and the register position in the file). linky dinky to my work

Impromptu project. Outside part is black PLA, light up part is clear PLA which should hopefully act as a half decent diffuser. I'll stuff some LED strips in behind to light everything up. Browsing what's out there to figure out the best/easiest way.

Also I'm back to using OpenSCAD because Fusion 360 is being a dick about fonts.

Also I'm back to using OpenSCAD because Fusion 360 is being a dick about fonts.

Funny. I read this article the other day and thought it was neat. Then I was in my local bar looking at their neon signs and was thinking that 3D printing 'neon' signs would be a great side hustle. They could even be marketed as 'green' since PLA is made from corn and LEDs are so efficient.

That said, you could look into using EL rope, like they do in the article.

all3dp.com

all3dp.com

That said, you could look into using EL rope, like they do in the article.

3D Printed Neon Sign: How To Make One in 3 Easy Steps

Elevate your space with LEDs that show off style and creativity. Check out all you need to know about creating your own 3D printed neon sign!

I looked at using EL wire, WS2812B strip, neon LED rope, white LED strip with colored rubbery strip and a bunch of other ideas... kinda felt like it would be a hands-on pain in the ass. the thought of bending and cutting and soldering a bunch of LED strips and cramming them down into a channel sounded like a giant pain in the dick.

I ended up deciding to go the WS2812B's-on-a-custom-PCB route because it doesn't cost much more and it's way the fuck easier. This thing arrives fully assembled from JLCPCB for me, I program it and screw on the 3D printed front with some self tapping screws and I'm done.

LEDs are placed. Gonna sneak on a USB-C power port, a couple tactile buttons to set brightness/colors/whatever, a microcontroller to run the board and she's done.

Might even get it ordered this evening, stormy day here and not much else to be at.

I ended up deciding to go the WS2812B's-on-a-custom-PCB route because it doesn't cost much more and it's way the fuck easier. This thing arrives fully assembled from JLCPCB for me, I program it and screw on the 3D printed front with some self tapping screws and I'm done.

LEDs are placed. Gonna sneak on a USB-C power port, a couple tactile buttons to set brightness/colors/whatever, a microcontroller to run the board and she's done.

Might even get it ordered this evening, stormy day here and not much else to be at.

Yeah, with that design EL would be a pain in the ass. But its a perfect replacement for neon.

Jehannum

Puts the "pro" in procrastination

Last edited:

Ape got a new phone, but the case won't be here until tomorrow (after we fly out). 3D printer to the rescue!

Jehannum

Puts the "pro" in procrastination

Jehannum

Puts the "pro" in procrastination

I've shot my first benchy at klipper.

Got a webcam mounted on the printer bed, klipper flashed to the printer, running on the pi, and I added a relay to the GPIO pins on the Pi to turn the PSU on and off. Probably should add another to turn on some LED strip lighting in the frame, too.

Turns out someone already wrote a plugin to handle the GPIO PSU stuff for octoprint too.

Got a webcam mounted on the printer bed, klipper flashed to the printer, running on the pi, and I added a relay to the GPIO pins on the Pi to turn the PSU on and off. Probably should add another to turn on some LED strip lighting in the frame, too.

Turns out someone already wrote a plugin to handle the GPIO PSU stuff for octoprint too.

Jehannum

Puts the "pro" in procrastination

If I don't like it, I can flash back to marlin in a heartbeat and just use octoprint that way.

Everyone I know who switched to Klipper has asked themselves why the fuck they haven't done it sooner. It's on my list of things to do, just haven't had the time to properly write up a configuration file for it.

Running a homemade 3D printer control board complicates things a bit.

Running a homemade 3D printer control board complicates things a bit.

Share: