ABS is just a dirty whore that loves to shrink and pull away from the bed. I haaaaate printing with it, and unless I've got a good reason to print with ABS (like, I'm making something that I'm solvent welding to ABS pipe) I go with PETG instead.

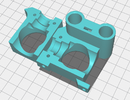

Using a brim helps. Especially with a print like the one you've got going there, which has sharp pointy corners where it'll likely break loose from the bed and cascade from there. Break the STL into two separate STLs and move them further apart from each other on the bed, so you can get more brim on the ends.

Enclosures help too, you can buy little 3D printer tents off amazon that seem pretty good. Creality makes an official one for the ender 3 etc.

Using a brim helps. Especially with a print like the one you've got going there, which has sharp pointy corners where it'll likely break loose from the bed and cascade from there. Break the STL into two separate STLs and move them further apart from each other on the bed, so you can get more brim on the ends.

Enclosures help too, you can buy little 3D printer tents off amazon that seem pretty good. Creality makes an official one for the ender 3 etc.