No, you just have it set to 4D mode. Switch it back to 3D mode and reprint. You should be good. Though, I would power cycle the printer so that you don't get quantum build-up.

Ontopic The 3D printing thread

- Thread starter gee

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mr. Argumentor

I fab shitboxes and shitbox accessories.

That wrinkles my brain

Mr. Argumentor

I fab shitboxes and shitbox accessories.

Jehannum

Puts the "pro" in procrastination

Everyone loves a good, quality dildo.

Jehannum

Puts the "pro" in procrastination

Jehannum

Puts the "pro" in procrastination

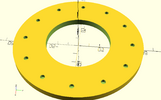

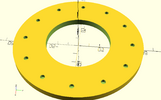

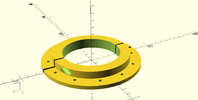

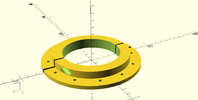

Helping a friend to make a tone wheel for his wheel speed sensors.

The holes are for mounting magnets that will trigger a hall effect sensor. The whole thing's parameterized, so the dimensions are purely fictional.

Gonna figure out what kind of retention strategy he wants, but a grub screw seems likely (so captive nut on the back facing the inner barrel of the rotor, then screw through it snugged up to the inside of the brake rotor.

The application is a '73 240Z with an 800HP Toyota 2JZGTE.

The holes are for mounting magnets that will trigger a hall effect sensor. The whole thing's parameterized, so the dimensions are purely fictional.

Gonna figure out what kind of retention strategy he wants, but a grub screw seems likely (so captive nut on the back facing the inner barrel of the rotor, then screw through it snugged up to the inside of the brake rotor.

The application is a '73 240Z with an 800HP Toyota 2JZGTE.

So this is gonna be a metal disc attached to the brake rotor? I'd worry that'll get hot enough to bring the magnets above their curie temperature, after which they won't be magnets anymore. And your metal's gonna have to be nonmagnetic or it'll shunt the magnets unless they protrude a fair bit.

I'd aim for a passive tonewheel instead of embedding magnets into something. Maybe just cut a bunch of slots in the disc.

I'd aim for a passive tonewheel instead of embedding magnets into something. Maybe just cut a bunch of slots in the disc.

Jehannum

Puts the "pro" in procrastination

It's attached to the hub, not the rotor. Not as much heat to worry about.So this is gonna be a metal disc attached to the brake rotor? I'd worry that'll get hot enough to bring the magnets above their curie temperature, after which they won't be magnets anymore. And your metal's gonna have to be nonmagnetic or it'll shunt the magnets unless they protrude a fair bit.

I'd aim for a passive tonewheel instead of embedding magnets into something. Maybe just cut a bunch of slots in the disc.

Mr. Argumentor

I fab shitboxes and shitbox accessories.

Helping a friend to make a tone wheel for his wheel speed sensors.

View attachment 13892

The holes are for mounting magnets that will trigger a hall effect sensor. The whole thing's parameterized, so the dimensions are purely fictional.

Gonna figure out what kind of retention strategy he wants, but a grub screw seems likely (so captive nut on the back facing the inner barrel of the rotor, then screw through it snugged up to the inside of the brake rotor.

The application is a '73 240Z with an 800HP Toyota 2JZGTE.

This guy does crazy shit with 3D printed insturments, https://www.youtube.com/channel/UCEHZvpVNGrVmb4i-39O3s4w

Jehannum

Puts the "pro" in procrastination

Yeah, I'm only meeting spec, not making those decisions.I'd still think a metal tone wheel would be easier to create, but whatever works for you.

Mr. Argumentor

I fab shitboxes and shitbox accessories.

Jehannum

Puts the "pro" in procrastination

Today on dildo making, I'm learning how to get ABS to adhere to my bed.

Tried (unsuccessfully):

* PVA on glass

* buildtak

* plain glass

Currently trying:

* hairspray on glass

I'd like to jack the bed temperature up a little more, but 105°C is already on the raggedy edge of what the printer's capable of.

Keep getting lifting during the print, that the hot-end snags on and causes a layer shift.

Still working on this particular dildo:

Tried (unsuccessfully):

* PVA on glass

* buildtak

* plain glass

Currently trying:

* hairspray on glass

I'd like to jack the bed temperature up a little more, but 105°C is already on the raggedy edge of what the printer's capable of.

Keep getting lifting during the print, that the hot-end snags on and causes a layer shift.

Still working on this particular dildo:

Mr. Argumentor

I fab shitboxes and shitbox accessories.

Jehannum

Puts the "pro" in procrastination

Well, I'm currently getting pretty good looking first layer with about .10 mm decreased distance between the nozzle and the bed, with some dry hairspray. We'll see how it does on down the line, but I'd rather not get all messy with ABS slurry yet. Probably kapton tape next.

Mr. Argumentor

I fab shitboxes and shitbox accessories.

Jehannum

Puts the "pro" in procrastination

Nope, just my office.You have a heated enclosure? Definitely can help ABS

Jehannum

Puts the "pro" in procrastination

Share: