My printer's direct drive. It started as the crappy "MK8" extruder that came with my A8, but I changed it out to a Trianglelab clone of an E3D Titan Aero, mostly out of hatred of the MK8.Anyone done a direct drive setup?

I keep eyeballing it, but I figure I should finish this BLTouch and E3D Nozzle upgrade

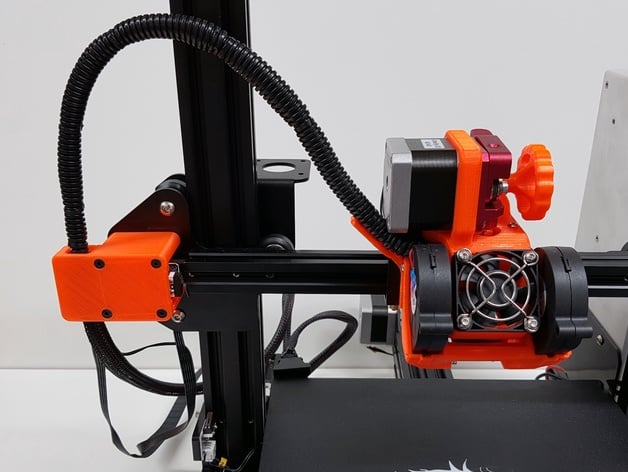

Direct Drive & Hero Me Remix 4 for Ender 3 & CR10S by BoothyBoothy

Update:19\06\20 Uploaded Step File. Jan 2020: It may be worth checking out my latest design - Hydra Fan Duct & Tool Change System which IMHO is far better in a lot of ways than this Hero Me remix. Link: https://www.thingiverse.com/thing:4062242 Update 04_10_19 Uploaded a Bridged 5015 duct with...www.thingiverse.com

In my experience, my Aero has no trouble printing TPU (granted, I've printed very few things with it), but the Ultimaker at work completely fails at it because there's too much slop in the tube. But for ordinary PLA/ABS/PETG/whatever printing, the Ultimaker and my own printer produce comparable output.